Got more work done on KT.

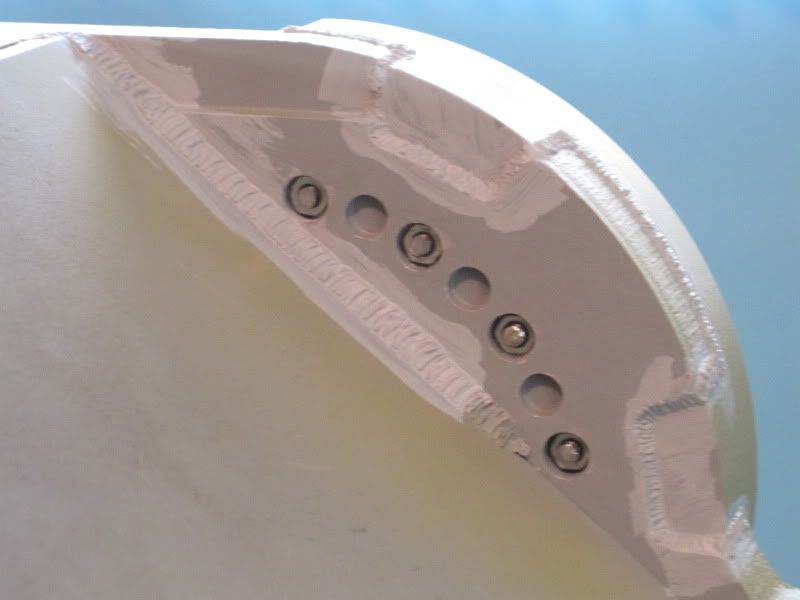

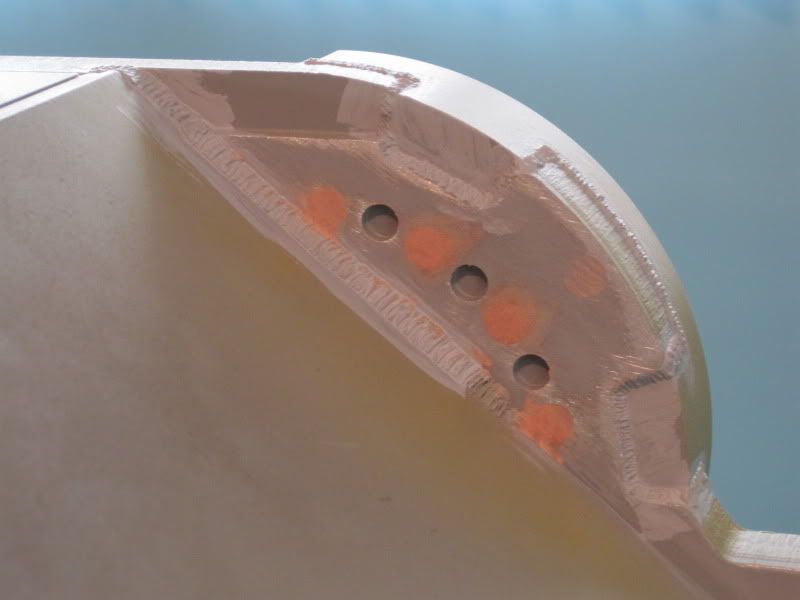

Here are the wheels all painted up, need to start weathering them.

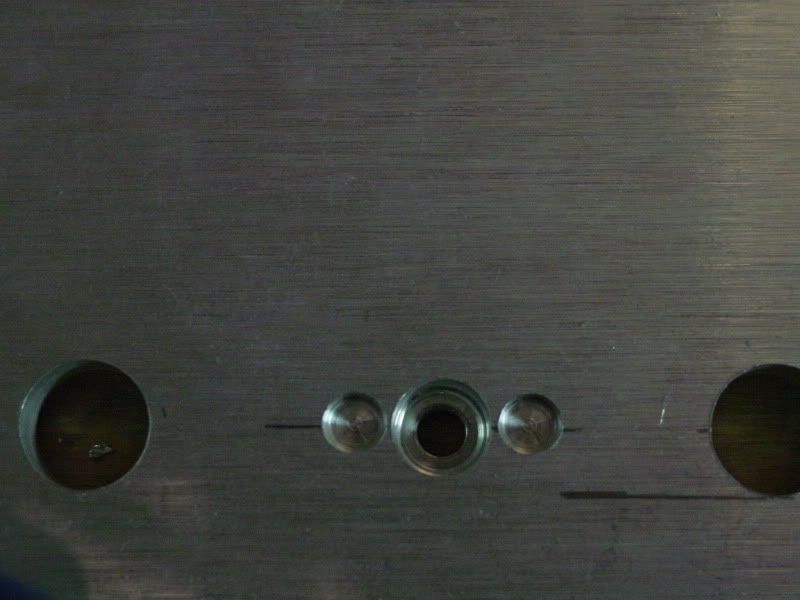

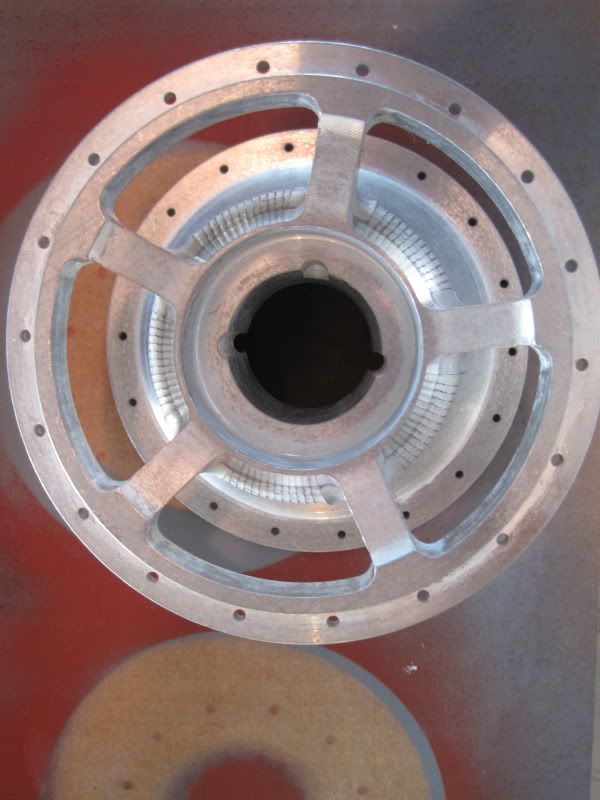

I used a 10ba nut and bolt with a small bead to represent the center fitting (not perfect but simple and dosn't look too bad).

I then tapped the holes with 8ba threads and used 8ba bolts with smaller heads.

I liked the look of it without the nuts on the back.

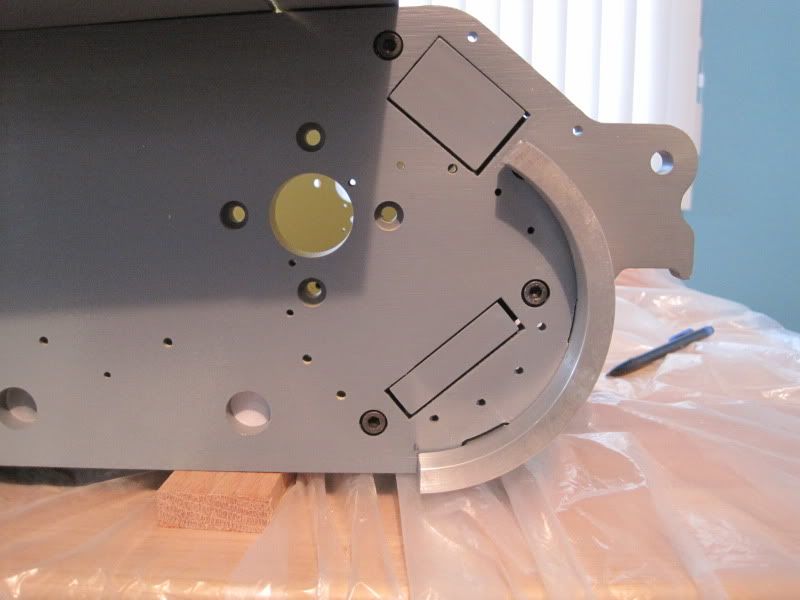

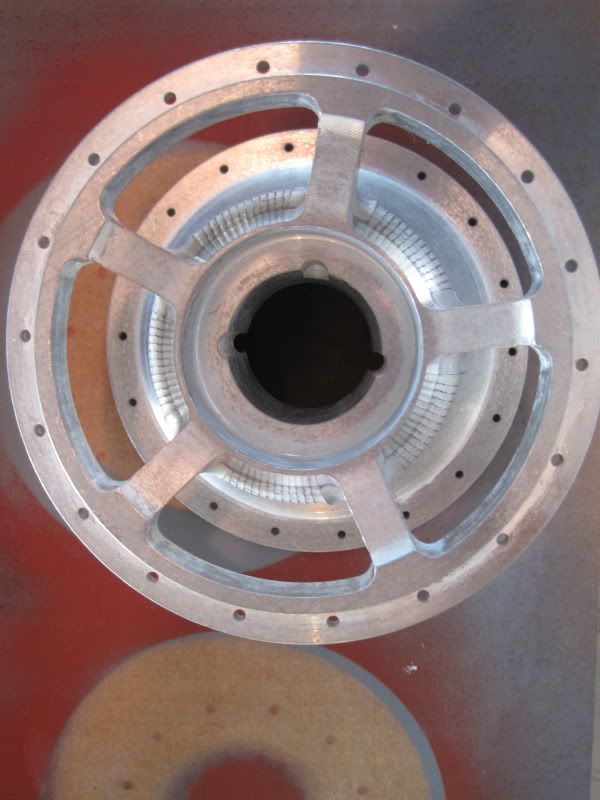

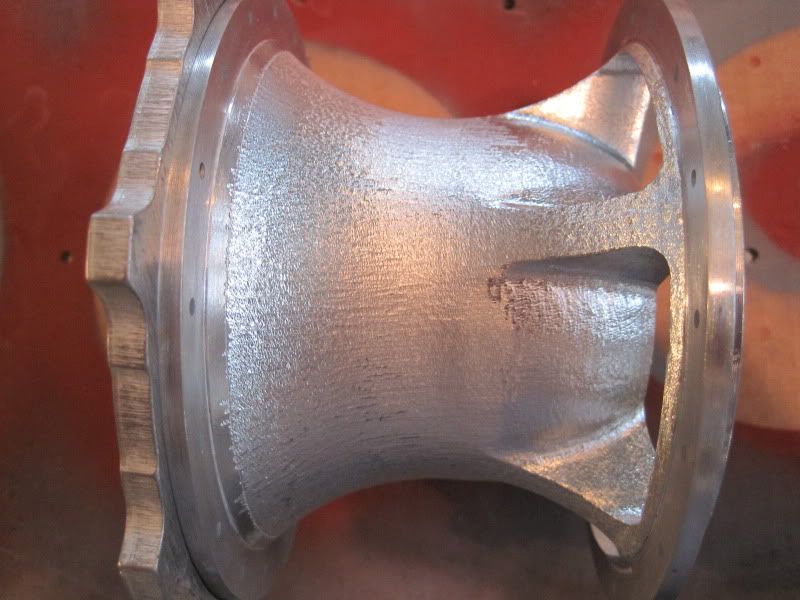

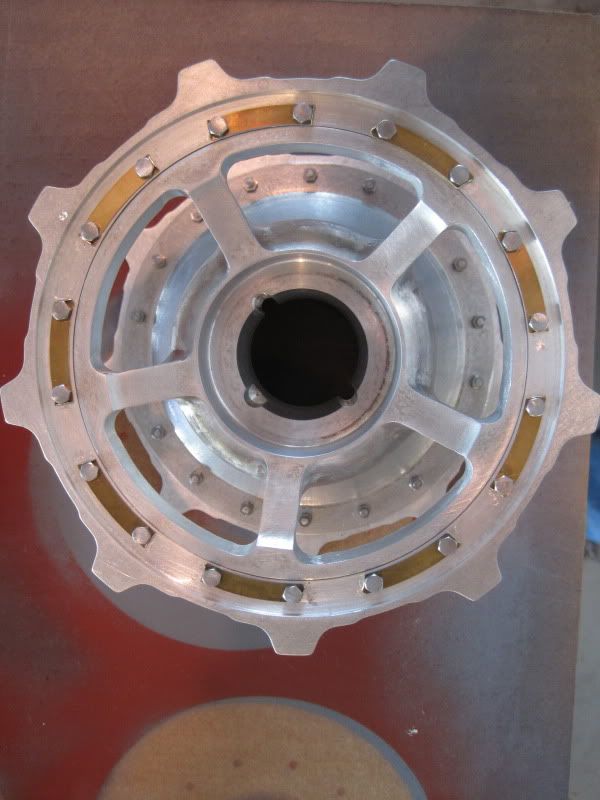

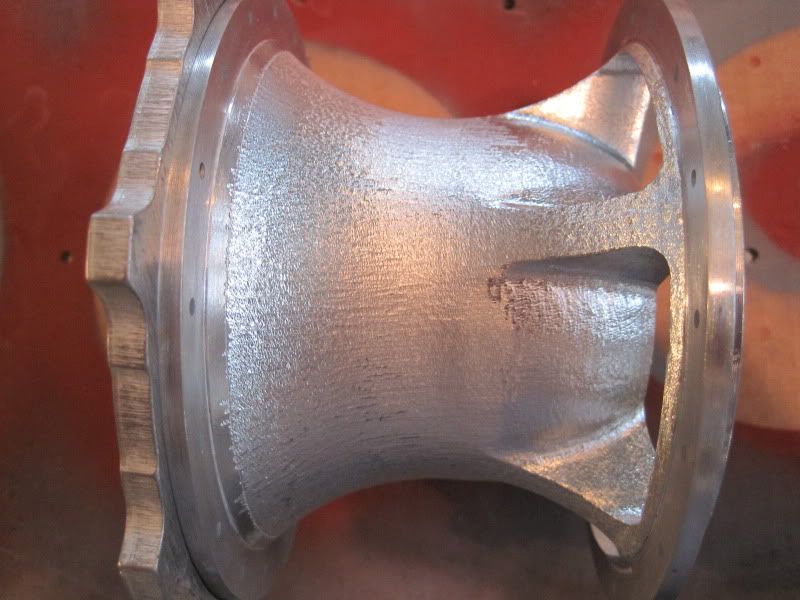

On to the drive sprocket. I sanded the milling lines out and then textured it with a dremmel.

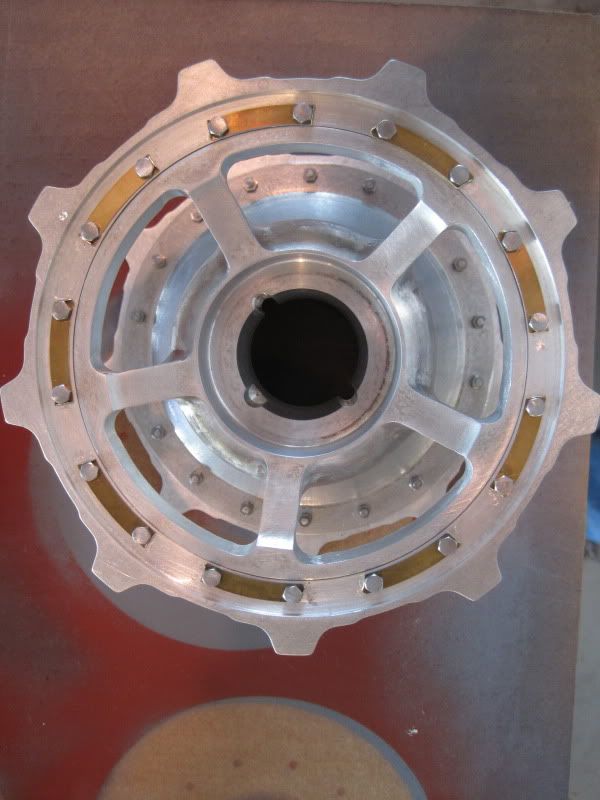

I then built the drive sprocket but deceided to try to move bolts outward. Here is before and after pictures.

Thats all for now. I need to practice my weathering skills before I attempt it on the wheels (still trying to figure out Simon's sponge weathering).

Joe