Main barrel recoil - anyone successfully done this?

-

Alan Hamby

- Posts: 44

- Joined: Fri Jul 13, 2007 12:37 am

- Location: Atlanta, GA, United States

- Contact:

Main barrel recoil - anyone successfully done this?

I know this has been discussed on the forum before but has anyone successfully created a recoil system for the main barrel? I'd like to use a recoil system on the barrel without the blank firer being installed. I just want the barrel to recoil realistically. I'm not using the Armortek blank firing system.

I believe the length of the stroke has previously been determined to be about 96mm. And the inward movement of the barrel needs to be quick while the outward recoil motion needs to be slower. I've read the discussions on programming servos to accomplish this.

What I'm wondering is has anyone successfully accomplished this?

- Alan

I believe the length of the stroke has previously been determined to be about 96mm. And the inward movement of the barrel needs to be quick while the outward recoil motion needs to be slower. I've read the discussions on programming servos to accomplish this.

What I'm wondering is has anyone successfully accomplished this?

- Alan

-

Paul Morris

- Posts: 1559

- Joined: Thu Jul 12, 2007 4:44 pm

- Location: North Lancs

- Been liked: 68 times

Main gun recoil.

Hello Alan.

Yes is the answer to your question, Clive Lockwood has made a very god recoil on his Tiger 1, it uses a large scale servo of the sail winch type with a long arm and a linear bearing fitted into the mantlet, it works very well in my opinion and Clive has also fitted the system into his very good scratchbuilt T.34 .

I think he may be on holiday at the moment {could be wrong} but drop him a P.M. he is a very helpfull fiendly fella and i am sure he will have a chat with you.

Hope this helps Paul

Yes is the answer to your question, Clive Lockwood has made a very god recoil on his Tiger 1, it uses a large scale servo of the sail winch type with a long arm and a linear bearing fitted into the mantlet, it works very well in my opinion and Clive has also fitted the system into his very good scratchbuilt T.34 .

I think he may be on holiday at the moment {could be wrong} but drop him a P.M. he is a very helpfull fiendly fella and i am sure he will have a chat with you.

Hope this helps Paul

Paul's Tank Workshop. Complete Tank builds and re builds zimmerit and paint to museum quality standard. pjtigerman@aol.com

01524 720977

https://www.facebook.com/PaulsTankWorkshop

01524 720977

https://www.facebook.com/PaulsTankWorkshop

-

Allan Richards

- Posts: 743

- Joined: Thu Jul 12, 2007 10:34 am

- Location: Kent

- Been liked: 10 times

-

Alan Hamby

- Posts: 44

- Joined: Fri Jul 13, 2007 12:37 am

- Location: Atlanta, GA, United States

- Contact:

-

Martin Cohen

- Posts: 136

- Joined: Wed Jul 18, 2007 2:59 pm

- Location: USA

- Been liked: 1 time

With the system as described, I wonder if it would be practical to somehow spring load the barrel in a way that it works against the servo causing the barrel to extend more slowly after firing than during recoil?

We might do well to follow-up with others who mentioned they were working on this:

Also note the posting by Roland Mann of Sep 05, 2008: "..Tiger I the information for the recoil I used to build my gun came from the "Prelaminary report No. 19" of the Military college of sience in November 1943. On page 4 the "maximum normal working recoil of 580 mm" is mentioned. This works out to 96,7 mm"

And around Nov. 2007 Robin Ellis posted some images of his Futaba servo, providing 3 to 4" recoil.

And going back to Oct. 2005, Matthijs Dijkstra had mentioned something about this "My machinist and I are developing a gas operated recoil recoil system!"

Just trying to help resurrect the idea,

Martin

We might do well to follow-up with others who mentioned they were working on this:

Also note the posting by Roland Mann of Sep 05, 2008: "..Tiger I the information for the recoil I used to build my gun came from the "Prelaminary report No. 19" of the Military college of sience in November 1943. On page 4 the "maximum normal working recoil of 580 mm" is mentioned. This works out to 96,7 mm"

And around Nov. 2007 Robin Ellis posted some images of his Futaba servo, providing 3 to 4" recoil.

And going back to Oct. 2005, Matthijs Dijkstra had mentioned something about this "My machinist and I are developing a gas operated recoil recoil system!"

Just trying to help resurrect the idea,

Martin

-

Lionel Champ

- Posts: 67

- Joined: Sat May 24, 2008 10:52 am

- Location: Dartford,Kent

- Been liked: 1 time

-

Paul Morris

- Posts: 1559

- Joined: Thu Jul 12, 2007 4:44 pm

- Location: North Lancs

- Been liked: 68 times

Hello Lionel.

I have wondered about this before and agree with you the Tamiya representation looks very very good,surely someone with the skill and machinery {like Mark } could perhaps make an enlarged version of the 1/16 recoil unit hint hint.

} could perhaps make an enlarged version of the 1/16 recoil unit hint hint.

Cheers Paul.

P.S. Clives is very good, but as Alan has pointed out with his similar set up it does not have the slowed down return....still good though

I have wondered about this before and agree with you the Tamiya representation looks very very good,surely someone with the skill and machinery {like Mark

Cheers Paul.

P.S. Clives is very good, but as Alan has pointed out with his similar set up it does not have the slowed down return....still good though

Paul's Tank Workshop. Complete Tank builds and re builds zimmerit and paint to museum quality standard. pjtigerman@aol.com

01524 720977

https://www.facebook.com/PaulsTankWorkshop

01524 720977

https://www.facebook.com/PaulsTankWorkshop

-

Roland Mann

- Posts: 174

- Joined: Thu Jul 12, 2007 4:45 pm

- Location: Stavenow, Germany

- Been liked: 19 times

Hi Alan, I remember the discussions very well in this forum regarding a recoil system. The reason I'm late here are my hesitations and respect of the strict policy of Armortek regarding blank firing the gun. I respect this very much and send you a PM with an intersting solution - promised.

Best regards Roland

Best regards Roland

Der Weg ist das Ziel.

-

Allan Richards

- Posts: 743

- Joined: Thu Jul 12, 2007 10:34 am

- Location: Kent

- Been liked: 10 times

Alan,

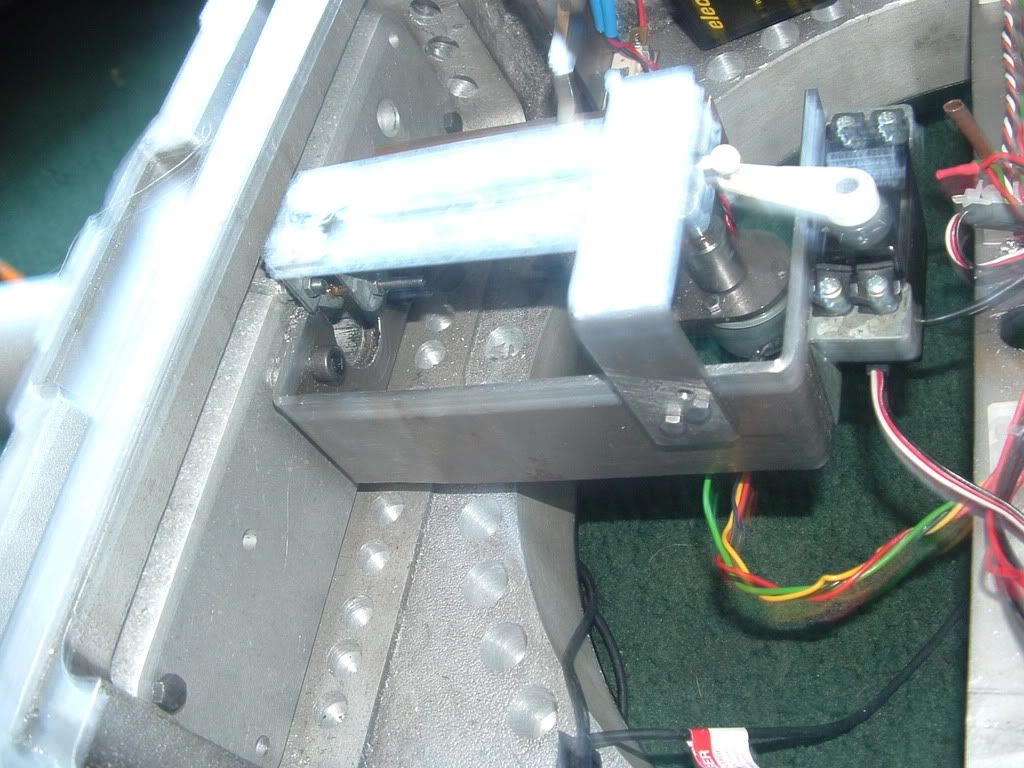

Sorry for the late reply but I've been away on business. The end of the barrel was drilled and tapped 3mm through its wall and a length of studding used to come back to the recoil system. Someone has suggested using a spring to give the differential velocity for recoil and recuperation but I fear that the servo I have used would not be strong enough to pull against a spring. It would be possible to make something along the lines of the Tamiya system but it would have to be much more robust to work with the much heavier barrel.

Sorry for the late reply but I've been away on business. The end of the barrel was drilled and tapped 3mm through its wall and a length of studding used to come back to the recoil system. Someone has suggested using a spring to give the differential velocity for recoil and recuperation but I fear that the servo I have used would not be strong enough to pull against a spring. It would be possible to make something along the lines of the Tamiya system but it would have to be much more robust to work with the much heavier barrel.

Allan Richards

-

Alan Hamby

- Posts: 44

- Joined: Fri Jul 13, 2007 12:37 am

- Location: Atlanta, GA, United States

- Contact:

I've been thinking about the fast rearward/slow forward movement problem, trying to relate it to anything I've seen in the real world. It may sound strange but what comes to mind is my kitchen drawers. I don't know what it's called but they have an "anti-slamming" or "soft close" feature. You can pull the drawer out normally as fast as you want, but when you slide it back inwards they reach a point and then slow down and automatically close slowly. It's just the same motion you'd want from the barrel. I know thats not much of a description but if you've ever seen this kind of drawer you'll know what I'm talking about. Here is an example of the pistons this mechanism uses:

http://www.toolstation.com/shop/Hardwar ... 674/p32435

I wonder if these could somehow be used to accomplish a realistic recoil?

- Alan

http://www.toolstation.com/shop/Hardwar ... 674/p32435

I wonder if these could somehow be used to accomplish a realistic recoil?

- Alan

-

Alan Hamby

- Posts: 44

- Joined: Fri Jul 13, 2007 12:37 am

- Location: Atlanta, GA, United States

- Contact:

Here's an example of how a soft close piston works:

http://www.youtube.com/watch?v=2C6Brg8yfOo

- Alan

http://www.youtube.com/watch?v=2C6Brg8yfOo

- Alan

-

Paul Morris

- Posts: 1559

- Joined: Thu Jul 12, 2007 4:44 pm

- Location: North Lancs

- Been liked: 68 times

Hello Alan.

I know exactly what you mean and i had similar thoughts myself in fact i actually got hold of a set of the drwer closers from work they are built on a quite substantial metal rail which i thought would support the weight of the barrel, i never got as far as trying it because i suggested it to someone and they just dismissed it as a none starter....but i may have a go now i know i am not alone.

Lets see what we can come up with between us.

Cheers Paul

I know exactly what you mean and i had similar thoughts myself in fact i actually got hold of a set of the drwer closers from work they are built on a quite substantial metal rail which i thought would support the weight of the barrel, i never got as far as trying it because i suggested it to someone and they just dismissed it as a none starter....but i may have a go now i know i am not alone.

Lets see what we can come up with between us.

Cheers Paul

Paul's Tank Workshop. Complete Tank builds and re builds zimmerit and paint to museum quality standard. pjtigerman@aol.com

01524 720977

https://www.facebook.com/PaulsTankWorkshop

01524 720977

https://www.facebook.com/PaulsTankWorkshop

-

Roland Mann

- Posts: 174

- Joined: Thu Jul 12, 2007 4:45 pm

- Location: Stavenow, Germany

- Been liked: 19 times

Hi Alan, some time ago a TIGER I modeller ask me if I could do a recoil system with the desired speed of movement. We discussed several methodes and I remeber the disadvantages of a servo for the reson of a fast recoil. The weight of the whole assembly to move backward ( when the gun is fired ) is no less than 5 kg. This has to be moved in less than 0.5 sec for the 80 or 90 mm. A small calculation equals to an enormes force, nothing for a set up like the Tamiya one. So next was an cylinder parallel to the gun to shift the whole thing back in 0.5 sec. The gas pressure was intended to come from a CO² cartridge. An old CO² pistol with trigger and valve was aquired. This solution came never to an end by problems to control the trigger. Too comlicated set up all in all with unsure processing details.

Last the idea of the gas cylinder suvived. The gun moves back in idle by a spring in the cylinder. Speed back is controlled by a small adjustable bleeding valve.

However, still the question how to provide the gas pressure for the cylinder. Probably some of you have the answer.

Roland

Last the idea of the gas cylinder suvived. The gun moves back in idle by a spring in the cylinder. Speed back is controlled by a small adjustable bleeding valve.

However, still the question how to provide the gas pressure for the cylinder. Probably some of you have the answer.

Roland

Der Weg ist das Ziel.

-

Alan Hamby

- Posts: 44

- Joined: Fri Jul 13, 2007 12:37 am

- Location: Atlanta, GA, United States

- Contact:

-

Alan Hamby

- Posts: 44

- Joined: Fri Jul 13, 2007 12:37 am

- Location: Atlanta, GA, United States

- Contact:

I've looked more at the Tamiya system. It seems like there should be a motor strong enough to duplicate this in 1/6th scale although it sounds like Roland may have tried it already.

Here is what the Tamiya recoil looks like in action:

http://www.youtube.com/watch?v=okpvV-hheNE

and

http://www.youtube.com/watch?v=Ix6RmdT76tQ

Here are drawings that allow you to see how the Tamiya recoil works. There is a cam on the big gear that attaches to the barrel and the big gear is turned by a worm gear arrangement:

It just seems that we should be able to duplicate this.

- Alan

Here is what the Tamiya recoil looks like in action:

http://www.youtube.com/watch?v=okpvV-hheNE

and

http://www.youtube.com/watch?v=Ix6RmdT76tQ

Here are drawings that allow you to see how the Tamiya recoil works. There is a cam on the big gear that attaches to the barrel and the big gear is turned by a worm gear arrangement:

It just seems that we should be able to duplicate this.

- Alan