Hi Mike

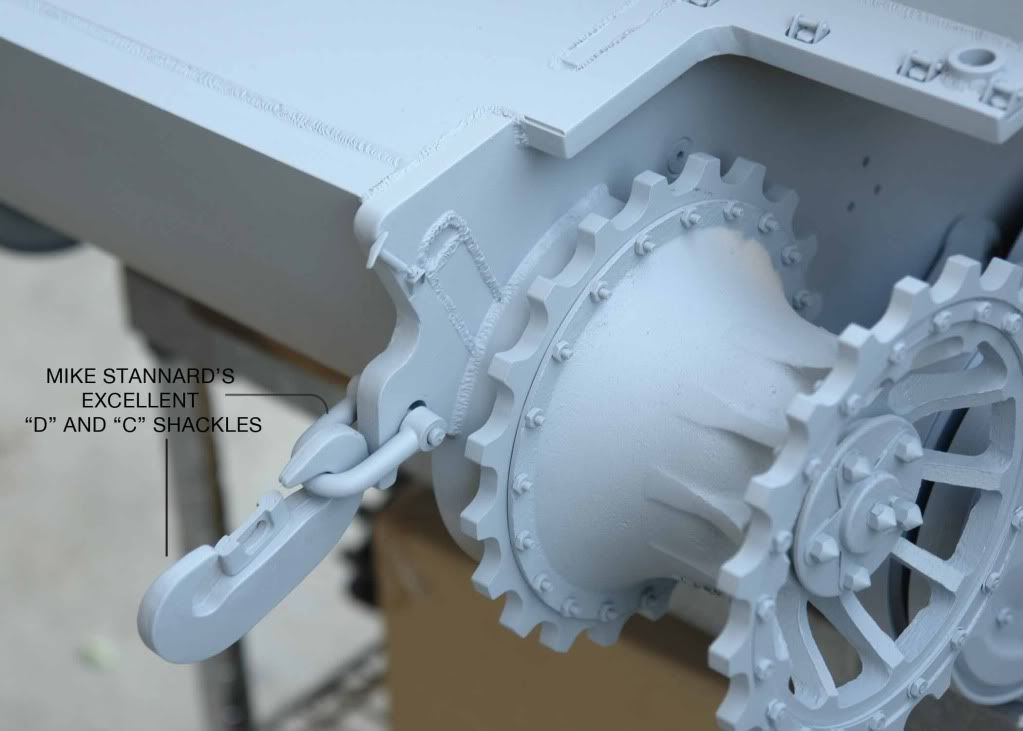

Thanks. They were an important detail for me. They look even better from a distance when you can see both of them. I have seen your handy work. The hooks will be a piece of cake for you.

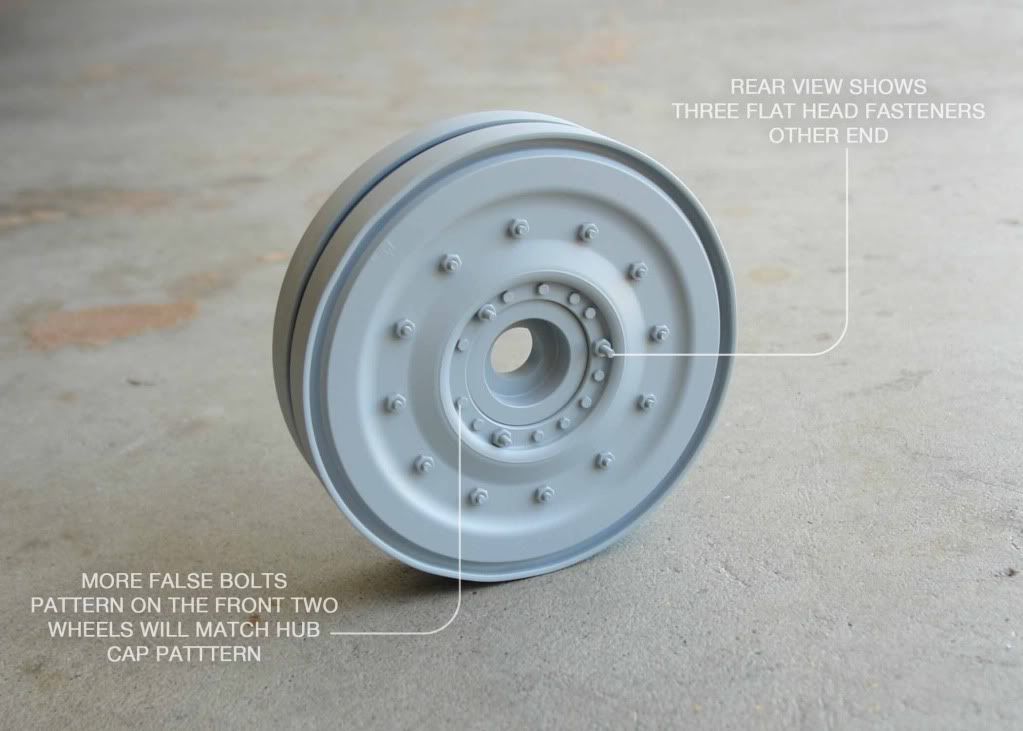

Dale jordan wrote:Plus how will you know which three nuts are the ones to undo when you need do take off the wheels ??

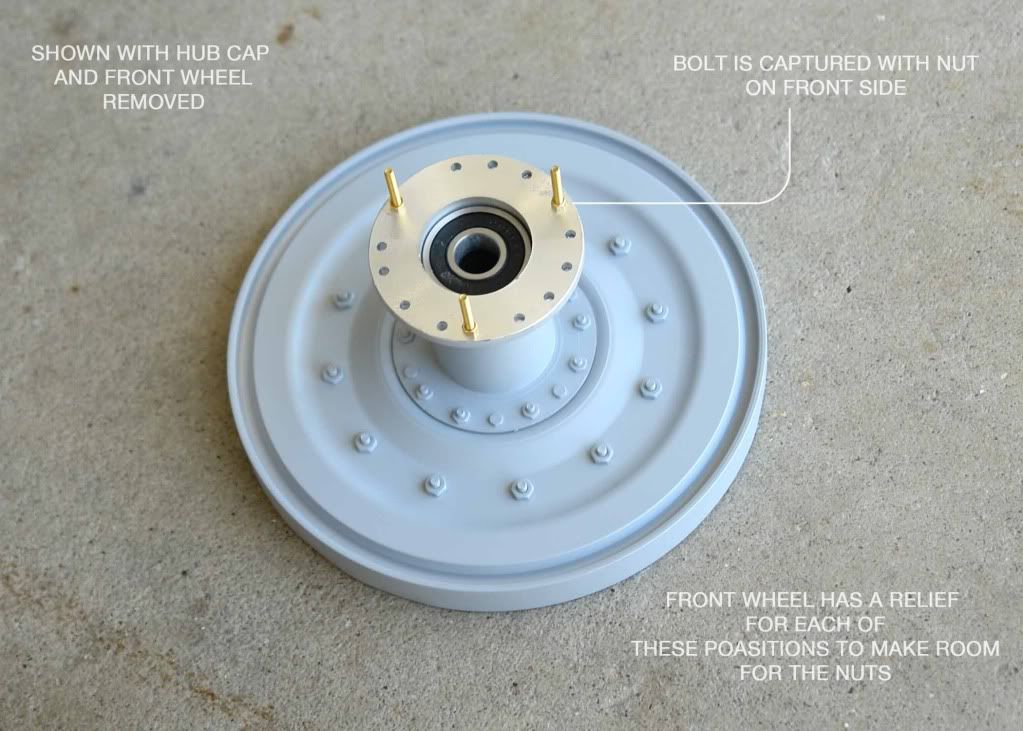

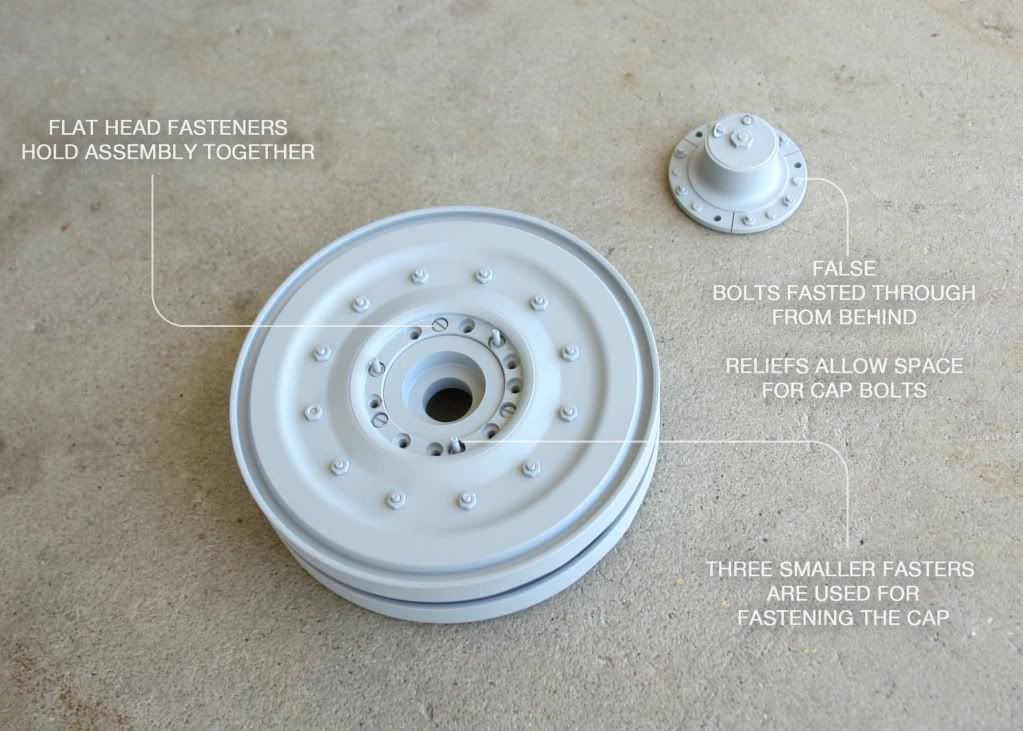

Dale, LOL I had the same thought. Fortunately the three bolts that hold the hub cap on run all the way through and are easy enough to find on the back side of the front wheel.

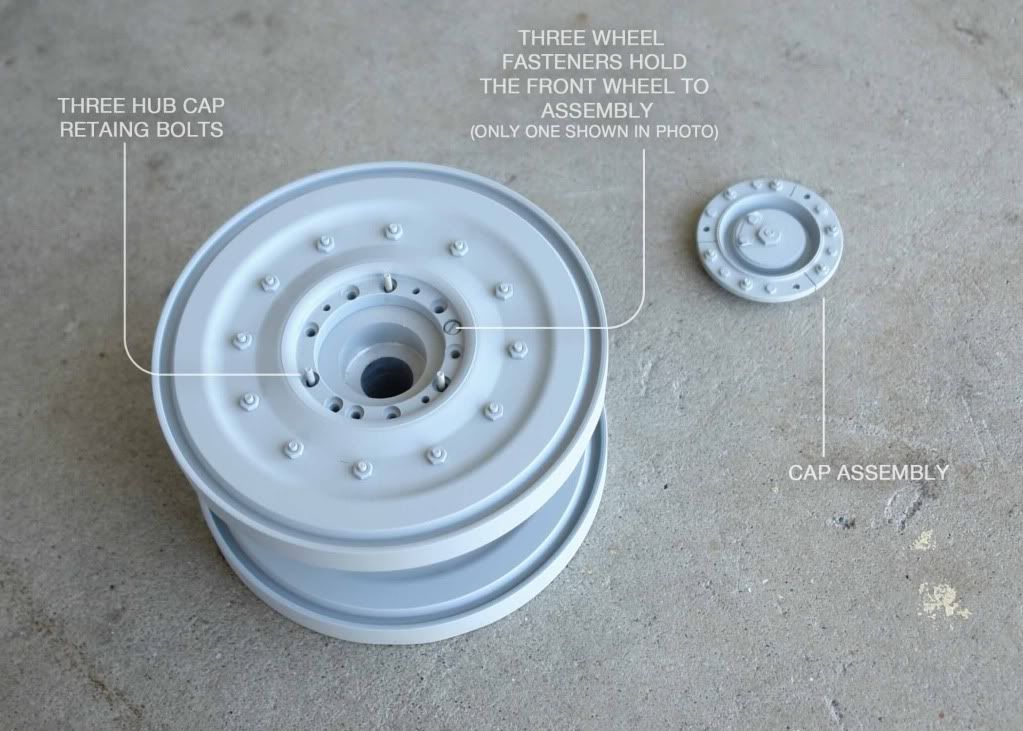

I'll take a photo without the front wheel mounted so you can see. They are held in place with a nut that holds them to the wheels center part. The wheel is simply slid over them and then the flat head fasteners are secured. I almost think the three fasteners would be enough. That way, when you remove those three nuts the hub and wheel come off together. Either way will work.

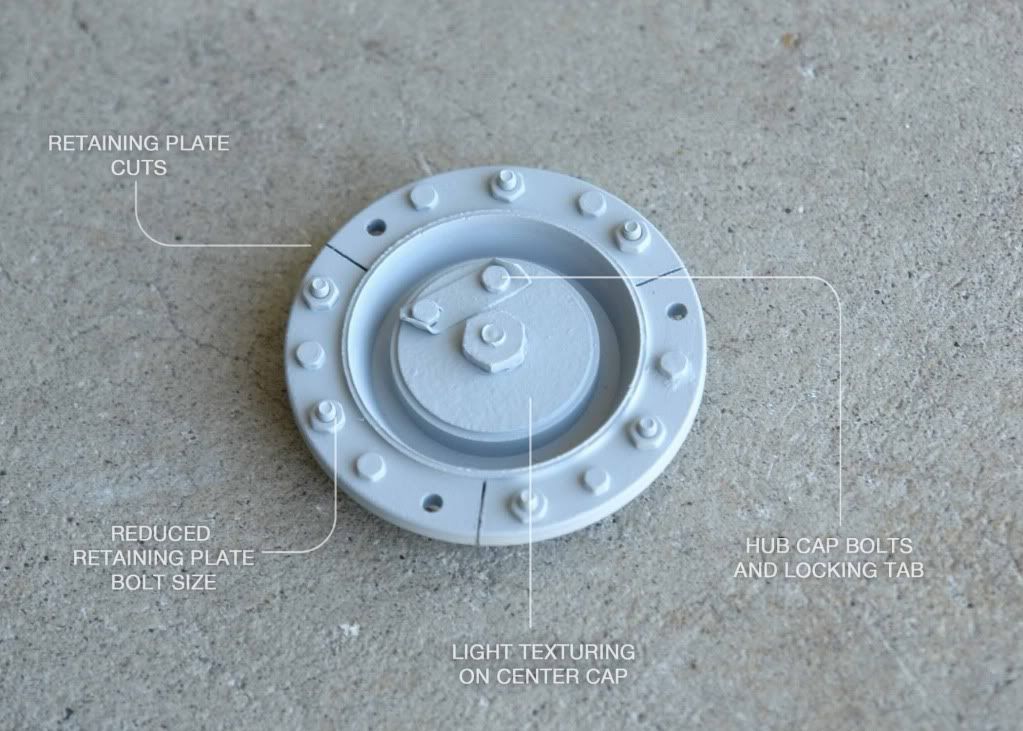

The recesses seen in the first photo around the holes are also to accommodate the bolts on the back side of the hub cap assembly. Sounds more complicated then it is. I'll be doing the rest of my wheels very soon.

The slots were cut with an Xacto saw.

regards

Tim

"So long as one isn't carrying one's head under one's arm, things aren't too bad." – Erwin Rommel